Improving Installation of Prefabricated Generator Exhaust Systems

Prefabricated generator exhaust systems have become an established replacement for field-welded assemblies. For years, generator exhaust systems have been made from sections of Schedule 40 carbon steel pipe, welded in the field and then insulated. But now, prefabricated systems have proven to save time and offer cost-effective safety in handling high temperatures and exhaust gas pressures.

But while prefabricated generator exhaust systems are superior products, projects can go awry if design and installation do not fall in line. In this blog, the experts at Schebler Chimney Systems share facts on installation to ensure that the system will operate with maximum efficiency.

Key Components

Key components of prefabricated engine exhaust systems, which include support plates, full angle rings, and bellows sections, need to be connected per Schebler’s installation drawings and instructions.

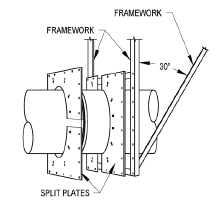

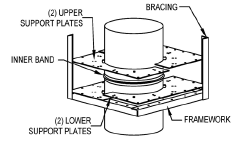

Support Plates – Schebler creates support plates for the system and these components are part of the UL listing. Support plates offer the greatest strength, both horizontally and vertically, and will provide proper joint alignment. Below are visual details for both horizontal and vertical support plate assemblies.

Horizontal view

Vertical view

Full Angle Ring and Hanger – The full rings and hangers are used to guide the chimney either vertically or horizontally. Hangers should be placed at intervals of no more than 12’ and securely connected to the building structure. Full rings should be spaced no greater than 16’ 6” through 10” diameters and 24’ for 12” through 48” diameters. The diameter of the full ring is slightly larger than the pipe, to allow the pipe to slide within the ring and accommodate thermal expansion.

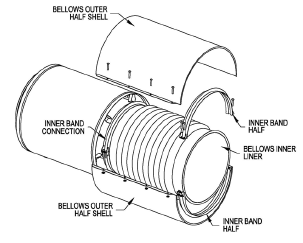

Bellows Section – The bellows section is used to compensate for thermal expansion in high-pressure applications, and is applicable to generator exhaust systems.  Ensuring a Safe, Reliable System

Ensuring a Safe, Reliable System

It is important to know how these key components interact with each other. Generator exhaust systems emit exhaust at temperatures anywhere from 500°F up to 1300°F, depending on the unit size, manufacturer, and type of fuel burned. As the system temperature increases, the system will experience thermal expansion, which can be absorbed by devices like the expansion bellows.

The system must be restrained and guided to ensure that thermal expansion is absorbed by the bellows, and not by the system’s joints or fittings. This creates a complex structural component that must be engineered for every system. An improperly designed and installed system has the potential to fail and leak harmful exhaust gas.

Usually, manufacturers will not supply structural design to secure supports and guides. It is important to select a manufacturer with an engineering department that can offer consultation and structural engineering services.

Referring to the system shown above, each run, vertical or horizontal, may include the following:

Support plates on each end. These require structural support framing at every location. The support frames need to be rigidly connected to the building to serve as an anchor point. This focuses the thermal expansion on the bellows sections. Angle iron should be used to frame and brace the support plates to guarantee proper install, and then connected to the structural steel. The details included under key components above show proper bracing and framework.

Bellows are included in straight runs no longer than 25’. If a straight run is longer than 25’, it is broken up into shorter sections with an additional support plate in between. The bellows section shown on the sketch does not include a cover just for clarity. They do come with a clam shell outer cover and are required for proper install.

Some runs may need additional guides in between the support plates. A full angle ring is included to act as an additional support or guide. This angle ring must also be rigidly connected to the building. The angle ring allows for linear expansion on the system. These are extremely important because they help keep the bellows in line. If they are not installed properly, the bellows can squirm as the system expands and contracts, which can have a huge impact on the joint connections.

Additional supports may be used in place of the support plate or the full angle ring, such as a wall support or a wall guide. These are included, just like the other supports, but are intended for exterior applications, such as up an exterior wall.

When working with prefabricated generator exhaust systems, it is important to pay attention to the specific components that apply to the layout of the system, and understand why and how they are used. The expertise of the Schebler Chimney team can help you to optimize the installation process.

To find out more about Schebler’s full line of chimney products and offerings, click here.

For more information, call (563) 359-0110 or visit www.scheblerchimney.com.

Related Articles

Fire Proof: Why UL Listed Chimneys Are an Essential Part of Our Design Solutions

Chimney and exhaust systems must safely handle extreme temperatures from smoke and steam or pose...Commercial Kitchen Exhaust Intro

Commercial Kitchen Exhaust Introduction It is important to design commercial kitchens for...Contact Us

Testimonials

Anthony Marmo (JMP) and Schebler engineering department worked seamlessly with the RF Knox drafting/design team to insure we were providing the customer with the perfect combination of space savings and performance. The oval (P2A) Chimney systems required less chase space, while providing the maximum amount of room possible and maintaining desired outer jacked temperatures per EOR design. The Schebler (P2A) flanged inner band connection was ideal for this application. The access to the horizontal installation area was a challenge and with the outer shell and inner shell being installed as one piece, it really made the install process half that of other slip joint products on the market and that we have used in the past. The QAQC process of verifying that all joints were made up and sealed also became an easier and more verifiable process. Win Win!

-Sean McNamara, R.F. Knox Company

Overall, Schebler Chimney brought real value in their team environment. Not only are they responsive, they are always willing to help and provide support. From beginning to end, they are an incredible asset and great resource. Even after a project they are there to stand by their work.

-Steven J. O'Connell, LEED AP, Atlantic Air Products.

The Schebler Chimney Systems team never fails to miss a beat investing time, energy and resources into providing unparalleled solutions for their customers. We look forward to continuing our partnership for years to come.