Fire Proof: Why UL Listed Chimneys Are an Essential Part of Our Design Solutions

Chimney and exhaust systems must safely handle extreme temperatures from smoke and steam or pose risks to people and property. This is especially true when that system is inside a large structure with multiple generators, in a commercial kitchen, or in a multi-use facility. But don’t leave the protection to chance: you need proof your chimney and exhaust system is up to the task. That’s why installing a UL listed chimney is so critical.

What does it mean to be UL listed?

UL stands for Underwriters Laboratories, the third-party certification company founded over 100 years ago. Now called UL Solutions, its mission is to help create a safer world, including supporting “the production and use of products which are physically and environmentally safe.” According to UL Solutions, the UL Mark is the single most accepted certification mark in the United States, appearing on 22 billion products annually. To receive a UL listed certification, products must meet specific safety and sustainability standards, including those preventing fire and electric shock.

A UL listing is the fire protection proof you need. Other companies provide similar safety assurances, but none are as stringent or as widely respected as a UL listing. Many alternative marks don’t do actual testing but merely make guesstimates based on product information. On the other hand, a UL listing means products have been rigorously tested for many variables, such as their structural integrity, after facing extreme conditions. While a UL listing gives users peace of mind, at Schebler, it also gives us peace of mind. Regardless of where our products go, whether into a children’s hospital or a high-rise apartment building, a UL listing demonstrates our products were designed correctly and for maximum safety.

Our UL Listed Chimneys Are 100% Approved

We should note that a UL listing is not a one-time event. To maintain a UL listing, UL Solutions performs quarterly inspections. They appear at a facility unannounced and with full access. They examine welds and inserts, perform density tests, measure part dimensions and even check product labels for accuracy. If UL uncovers a violation, they have the authority to completely halt production.

At Schebler, we’re proud that we have been UL Certified since 1994, and in all that time, we have never had a single major violation.

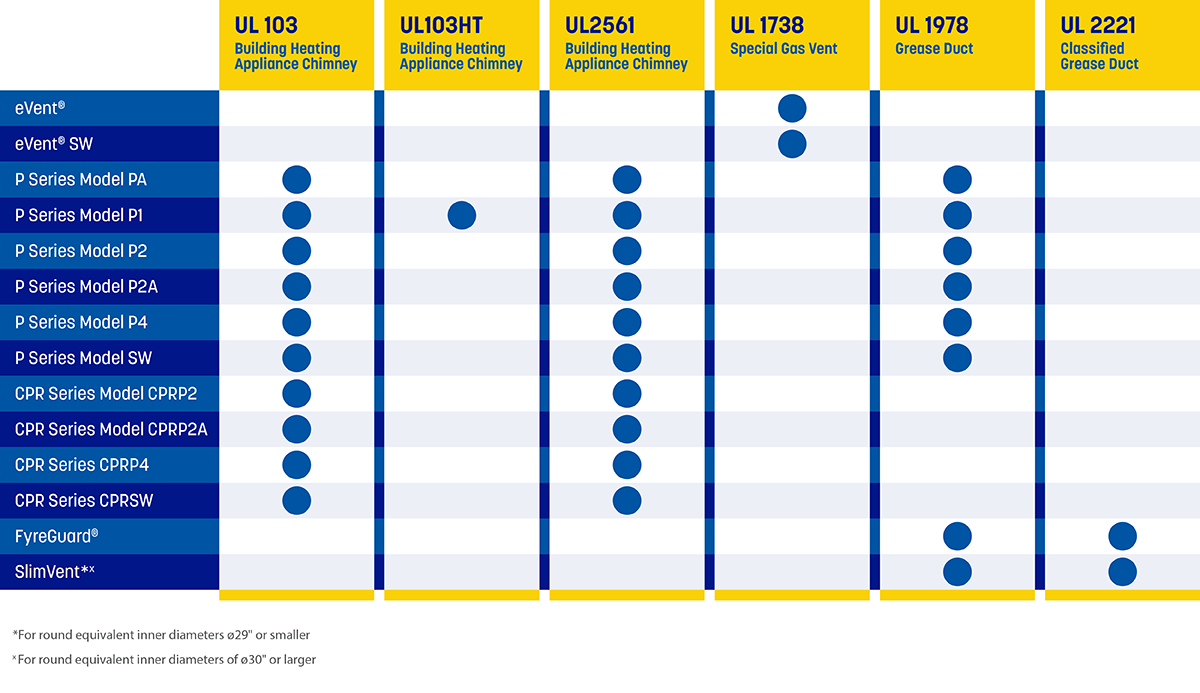

What Do Schebler’s Specific UL Listings Mean?

There are more than 1,500 different UL Standards, and each number represents a different application and level of protection. At Schebler, we know our listings front and back, enabling us to match our products to your needs and ensuring our UL listed chimney meets your specific criteria.

Here are some UL listings you’ll find on Schebler products.

UL 103: For Safety Factory-Built Chimneys

UL 103 covers factory-built chimneys intended for venting gas, liquid and solid-fuel fire appliances and are rated to perform up to 1000ºF (538º C). To earn this listing, these chimneys undergo intensive heat testing. Although they are rated to continually perform in temperatures up to 1000ºF, they are tested to withstand temperatures as high as 1700ºF (927º C).

UL 2561: For Safety 1400 Degree Fahrenheit Factory-Built Chimneys

UL 2561-rated factory-built chimneys can withstand hotter temperatures than UL 103-rated ones—as high as 1400ºF (760º C), continually. Most of our products also meet this difficult standard.

UL 1738: Venting Systems for Gas-Burning Appliances

UL 1738 requires that certain gas-fired appliances, such as boilers, have venting materials that are corrosion and degradation-resistant. These products must successfully pass a variety of environmental tests and must be able to withstand the constant heat for at least 8-10 years.

- UL 1738 Schebler Products: eVent™ Series

UL 1978: For Safety Grease Ducts

UL 1978 specifically covers factory-built grease ducts and grease duct assemblies with reduced clearances. UL 1978 products undergo extensive testing to ensure they are fire-resistant, don’t leak, and can be safely cleaned. The standard is similar to UL 103 but with additional fire protection requirements.

For one of the many UL 1978 tests, UL inserts 20 pounds of lard inside a duct and then lights it on fire. After the fire burns out, the duct is weighed in order to determine how much of the original grease remains. If the duct is too light, it means some grease has leaked out, which equals failure.

- UL 1978 Schebler Products: P Series models PA, P1, P2, P2A, P4 and Single Wall (SW); FyreGuard®; SlimVent®

UL 2221: For Safety Tests of Fire Resistive Grease Duct Enclosure Assemblies

UL 2221 sets rules for tests to determine the fire resistance of grease duct enclosure assemblies. These tests measure combustibility, surface flammability, and smoke generation potential, among other things. These tests evaluate how well a grease duct enclosure can contain an internal fire and repel an external one.

To meet the UL 2221 standard, a grease duct must first be listed as UL 1978, and then it must meet additional testing challenges. In one example, a duct is heated to 2000 degrees above the ambient temperature for two hours. Thirty-two separate temperature monitors are placed in the duct to ensure the product adequately maintains its integrity throughout the test. The assembly is then hung from a concrete slab and submerged in a 2000-degree furnace. Finally, it is lifted up and hit by a continual hose stream. This mimics a fireman bombarding the duct with a fire hose. All of this is done to ensure its structural integrity is not compromised.

- UL 2221 Schebler Products: FyreGuard®, SlimVent®

Schebler UL Listed Chimneys: The Certainty of Safety

As a building owner or manager, the relief of knowing your facility and the people inside are safe cannot be overstated. It’s our number one priority. At Schebler, we’re about certainty—the certainty of dependability and value, but also the certainty of safety. For us, UL listed chimneys aren’t optional; they are a vital part of our product offerings.

If your chimney and exhaust system components lack the UL Mark, then you’re playing with fire. Literally. For ultimate security and protection, look for Schebler UL listed chimneys. Schebler products are also backed by outstanding quality, impressive warranties and first-class support.

Contact us to learn more.

Related Articles

Congrats, Brad Zogg!

Congratulations to Brad Zogg - President! The Schebler Company is very pleased to announce that...Commercial Kitchen Exhaust Intro

Commercial Kitchen Exhaust Introduction It is important to design commercial kitchens for...Contact Us

Testimonials

Anthony Marmo (JMP) and Schebler engineering department worked seamlessly with the RF Knox drafting/design team to insure we were providing the customer with the perfect combination of space savings and performance. The oval (P2A) Chimney systems required less chase space, while providing the maximum amount of room possible and maintaining desired outer jacked temperatures per EOR design. The Schebler (P2A) flanged inner band connection was ideal for this application. The access to the horizontal installation area was a challenge and with the outer shell and inner shell being installed as one piece, it really made the install process half that of other slip joint products on the market and that we have used in the past. The QAQC process of verifying that all joints were made up and sealed also became an easier and more verifiable process. Win Win!

-Sean McNamara, R.F. Knox Company

Overall, Schebler Chimney brought real value in their team environment. Not only are they responsive, they are always willing to help and provide support. From beginning to end, they are an incredible asset and great resource. Even after a project they are there to stand by their work.

-Steven J. O'Connell, LEED AP, Atlantic Air Products.

The Schebler Chimney Systems team never fails to miss a beat investing time, energy and resources into providing unparalleled solutions for their customers. We look forward to continuing our partnership for years to come.